The production control system developed by Beijing Soly Technology Co., Ltd. has been designed to optimize the production processes in the mining industry. By integrating advanced technology with data-driven insights, the system aims to improve efficiency, reduce operational costs, and enhance overall productivity. This innovative solution has garnered attention from industry experts and mining professionals alike.

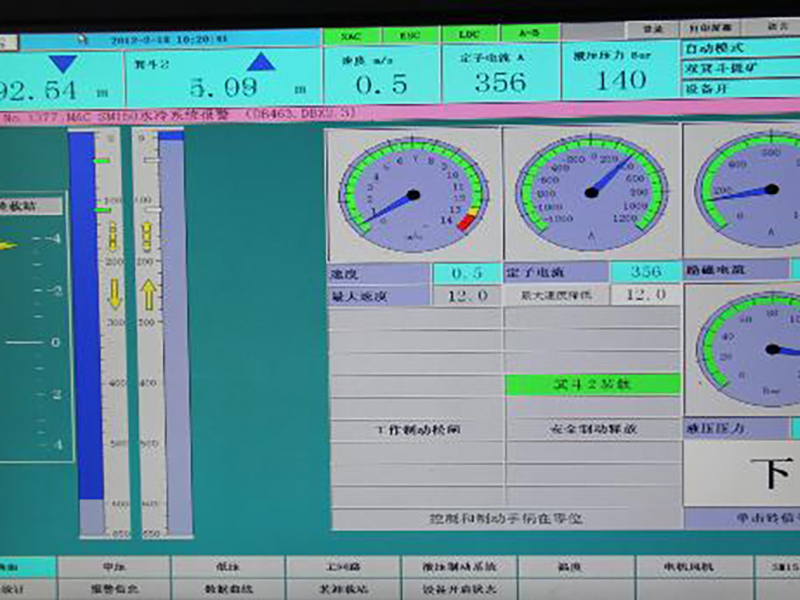

The production control system developed by Beijing Soly Technology Co., Ltd. leverages the power of big data and analytics to monitor and manage various aspects of mining operations. From equipment performance and maintenance to resource allocation and supply chain management, the system provides real-time insights and actionable intelligence. This enables mining companies to make informed decisions, streamline their processes, and maximize their output.

One of the key features of the production control system is its ability to optimize equipment utilization. By analyzing the performance of mining machinery and vehicles, the system can identify potential bottlenecks and inefficiencies. This allows for proactive maintenance and scheduling, ensuring that equipment is operating at its peak performance level. As a result, mining companies can minimize downtime, extend the lifespan of their assets, and ultimately, reduce operating costs.

Furthermore, the production control system offers comprehensive inventory management capabilities. By tracking raw materials, supplies, and spare parts in real-time, the system enables mining companies to maintain optimal inventory levels while avoiding stockouts or excess inventory. This not only improves resource utilization but also contributes to cost savings and improved overall operational efficiency.

In addition to equipment utilization and inventory management, the production control system also enhances safety and compliance in mining operations. By monitoring environmental conditions, worker activities, and regulatory requirements, the system helps mining companies to identify and address potential safety hazards and compliance issues. This proactive approach not only minimizes the risk of accidents and incidents but also ensures that mining activities align with industry regulations and standards.

The implementation of the production control system has already delivered significant benefits to Shougang Group Mining Company and other affiliated entities. By harnessing the power of advanced technology and data-driven insights, Beijing Soly Technology Co., Ltd. has helped improve operational efficiency, reduce costs, and enhance overall productivity. As a result, the company has solidified its position as a leader in the mining technology space.

Looking ahead, Beijing Soly Technology Co., Ltd. continues to innovate and expand its portfolio of solutions for the mining industry. With a strong commitment to research and development, the company aims to address the evolving needs and challenges of the mining sector, offering tailored solutions that drive sustainable growth and success.

In conclusion, Beijing Soly Technology Co., Ltd.'s production control system represents a significant leap forward for the mining industry. By leveraging technology, data, and insights, the system has the potential to transform mining operations, driving efficiency, productivity, and safety. As the company continues to push the boundaries of innovation, it is poised to shape the future of mining technology and redefine industry standards.